DELIVERY TIME: 4-10 working days

Shipping calculated at checkout

Prices per nozzle & ex-vat

Click here for High Level soft wash nozzles

Click here for Rinsing soft wash nozzles

These nozzles are designed to fit our 1/4" stainless steel couplings, which are necessary to fit the nozzles onto the outlet of our low-level and mid-level lances.

They come with either a 6.5, 10 or 15 tip, which are easier and quicker to interchange than the lighter high-level nozzles. This saves considerable time when soft washing garden walls, for example and is why we have introduced them for low-level soft washing.

These stainless steel couplings are too heavy to fit on the end of a water fed pole. For high-level chemical application nozzles please see our high-level application nozzle page. This is a much lighter nozzle suitable for high-level application of softwash chemicals.

How to choose the correct size of softwash nozzle

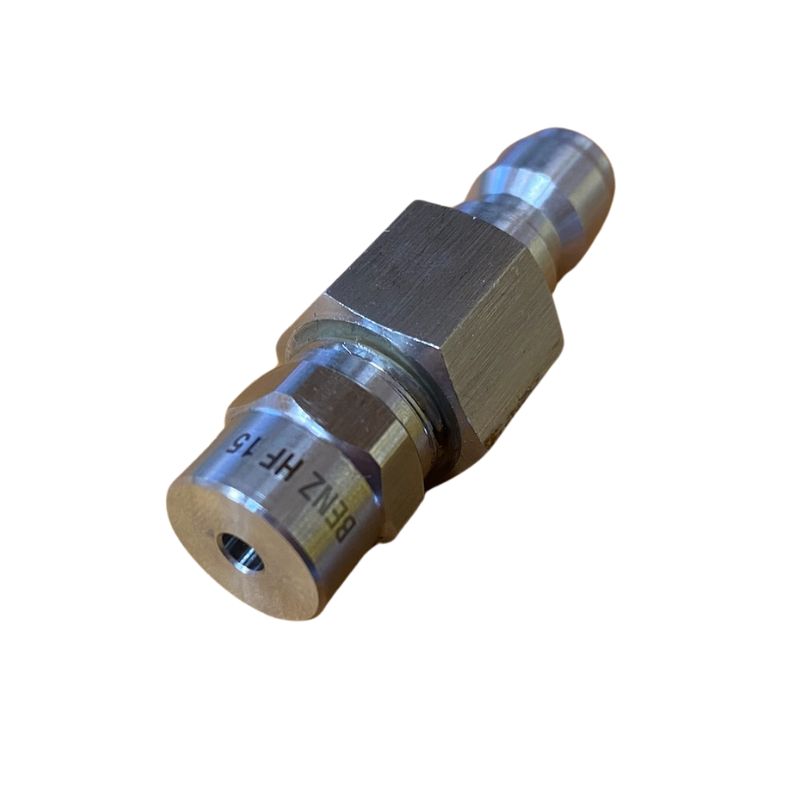

Benz softwash spray nozzles deliver a cone-shaped pattern to the surface and are available in three sizes of nozzle tips: 6.5, 10 and 15.

You'll find the size of tip stamped on the face of the nozzle.

The numbers relate to ratings for fluid delivery in litres per minute at 6 Bar (for example the 10 tip is rated at 10 l/pm at 6 Bar).

In less technical language the smaller the number on the tip, the smaller the orifice or size of outlet of the nozzle. Benz softwash chemicals perform differently when used with different sizes of orifice.

The 6.5 is great for applying Benz Bio Cleanze. It's smaller orifice gives a greater pressure of chemical delivery, helping to more effectively penetrate deep into the biological growth that's responsible for the unsightly staining your customer wants removed.

It's suitable for flow rates up to 6 l/pm (at the nozzle) without creating excessive spray drift and can be used with small 12v pumps. Higher pressure pumps can be used if they are regulated to around 6 l/pm.

The 10 is best suited for the low pressure application of Benz Lightning Cleanze. It offers higher flow rates when using a small pump, such as 100 psi 5 l/pm pump commonly used for window cleaning, and reduces spray drift to a minimum.

The 10 nozzle is suitable for flow rates up to 2 l/pm (at the nozzle) without creating excessive spray drift.

It can also be used for Bio Cleanze application up to flow rates of 4 l/pm but does not have the same pressure of delivery as the 6.5.

The 15 is best suited for the low pressure application of Benz Lightning Cleanze at higher flow rates. It can be used with the larger softwash pumps such as the Comet or Rolltec.

This nozzle is suitable for flow rates up to 10 l/pm (at the nozzle) without creating excessive spray drift.

Understanding flow rates

By reducing the size of the hole in the nozzle – the orifice – the output pressure and velocity increases – but this restricts the flow of fluid, so the flow rate decreases.

To best understand this, think of squeezing a garden hose at the end. The water will spray further but the flow rate will be reduced. To cover the same distance with same flow would need more energy (i.e. a bigger pump).

The 10 offers higher flow rates than the 6.5 when using a similar pump because the orifice is bigger. There will be less or more spray drift according to the different flow rates and pressure, which is why we choose the 10 over the 6.5 when using Lightning Cleanze with a 100 psi 5 l/pm window cleaning pump.

What flow rate do you need for each softwash nozzle?

Set the flow-rate of your softwash pump so the flow-rates at the nozzle "in use" are:

Lightning Cleanze: 1-2 l/pm with 10 nozzle or 2-4 l/pm with 15 nozzle

Bio Cleanze: 2-6 l/pm with 6.5 nozzle

The simplest way to determine if the flow rate is correct, is to observe the amount of softwash chemical going onto the surface. If there's too much and you can see a lot of unnecessary run-off, turn the flow-rate down. If there's not enough softwash chemical reaching the surface, turn the flow-rate up. You will get a "feel" for this with experience.

For example, for most porous wall renders applying Bio Cleanze at 10 l/pm would deliver too much chemical too quickly without allowing it to soak deep into the substrate And there would be a lot of spray drift.

Whereas 10 l/pm can be fine for some large flat roofs, car parks, and in general any large horizontal area where fast application is desirable and overspray is not a problem.

If you want to check the flow-rate more precisely, simply direct the jet into a bucket for one minute. Then measure the quantity of chemical in the bucket.

For example, if there's 2L in the bucket your flow-rate is 2 l/min. And so on.

Quick tip: There are too many variables, such as hose diameter, type of pump, pressure, material the surface is made of, and so on, to give a one-size-fits all static figure for the best flow rate for a given surface.